Josh Gess is in a sweet spot for creating novel solutions for the thermal management of computer technology.

“Right now, we’re strategically positioned to turn and burn on three- to six-month industry projects at scale,” said Gess, associate professor of mechanical engineering at Oregon State University.

Since joining the faculty in 2015, Gess has pursued more effective and efficient liquid cooling methods to manage the intense heat generated by microelectronics, which can reduce performance and even cause failure. And the new microfabrication facilities at the Jen-Hsun Huang and Lori Mills Huang Collaborative Innovation Complex, set to open in early 2027, will enable Gess to broaden his research capabilities.

Gess emphasized that his lab is product oriented and is enthusiastically seeking industry partners to expand research at the vanguard of computer cooling technology. He’s currently working with organizations — including HP, Microsoft, and the National Science Foundation — on projects ranging from the nano- to the macro-scale.

“Before industry and granting agencies began focusing on cooling semiconductors, cooling was considered a second-tier issue. They were more concerned about the demand for electricity to power microchips used for artificial intelligence and mammoth data centers,” Gess said. “Along with major changes in technology, there’s been enormous increases in heat density, and the amount of power needed to cool down large systems often matches the power used for computing itself, so thermal management has become a critical design driver. I think keeping increasingly powerful devices cool and reliable is one of the computer industry’s most important problems.”

Immersion cooling for servers

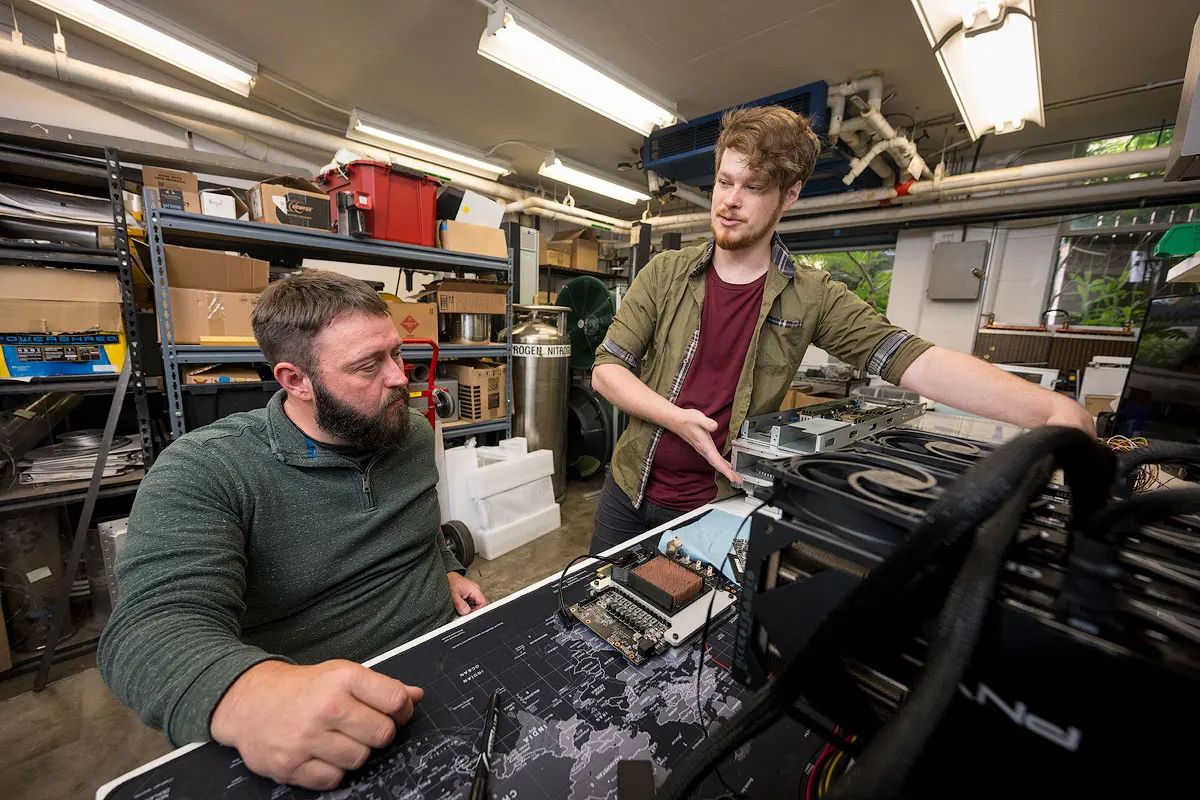

One project, funded by Microsoft, that Gess is leading is aimed at cooling servers by immersing them in dielectric oil.

“We’ve built a system where the server box is the heat sink,” Gess said. “Effectively, it’s a very large active heat spreader, robust enough to prevent leaks and making implementation at the rack scale safer, more cost-effective, and more palatable for industry.”

Gess and his team are developing a sealed, computationally dense, single-phase liquid immersion-cooled server chassis, which represents an evolution from previous sponsor-supported work. The chassis will house a multi-GPU server assembly in a full-width, leak-tight 3RU chassis retrofittable to existing air-cooled rack configurations. To meet the thermal demands of high heat loads, the design incorporates two parallel approaches: “lay-in” heat exchangers with high-density skived fins for increased surface area and thermal transfer, and direct bonding of an optimized heat sink to an underlying vapor chamber using additive manufacturing, thus eliminating the parasitic thermal interface material conventionally used to bond heat sinks to an integrated heat spreader.

Early testing with modified modules will guide component placement, coolant distribution, and integration of internal fluid movers targeting high-energy-density components. The primary goal is developing a liquid immersion–cooled chassis for immediate adoption by industry.

“The boom in AI is happening now, and industry needs solutions now,” Gess said. “Jensen Huang famously said that AI is ‘power limited.’ The product-oriented, energy-efficient design philosophy of our team aims to build a system that reduces the ask for local power grids or facilitates reallocation of that precious power back to the server, increasing outputs and profit.”

Microfluidic system for chip cooling

In a study funded by HP and the Oregon Metals Initiative, Gess and his colleagues are developing an internal cooling system for 2.5D and 3D stacked microchips.

“There’s no question that 2.5D and 3D stacked microchips will become commonplace, but managing the heat they produce is critical, especially for 3D chip integration,” Gess said.

With 2.5D chip integration, chips are arranged side by side on a shared interposer. In contrast, 3D chip integration involves multiple chips that are stacked vertically on top of each other and connected through vertical interconnects — all on a silicon wafer that’s 250 to 400 microns thick. Cooling 2.5D integration is somewhat more difficult than cooling conventional chip configurations.

Cooling 3D stacked chips, however, is considerably more challenging. One major reason is that only the outside surface of the stacked chips can dissipate heat through external cooling systems, while heat from inner layers becomes trapped inside, so traditional cooling methods often can’t keep up.

To address the cooling challenge, the researchers created an embedded microchannel network throughout the interior of the stacked chip assemblies. A liquid coolant flowing through the channels enables the microfluidic system to transfer and remove heat from the chip’s interior. It also helps to control boiling and vapor congestion inside microchannels, making the cooling process more efficient and reliable.

Another factor that distinguishes the system is its ability to measure heat transfer and temperature changes in real time at an extremely small scale — something not possible before. This detailed monitoring will help prevent overheating issues that can cause chips to fail, especially when cooling systems get clogged or coolant flow is disrupted.

The team will also develop new scientific models for understanding how heat moves through these systems, using data from embedded sensors within the cooling channels. These models can inform the design of better cooling systems not only for electronics but for any application where compact, high-performance heat exchange is needed.

By the project’s end, the team expects to deliver validated metrology-enabled microscale heat exchangers and sensor-integrated thermal test vehicles, which will represent a leap forward in energy-efficient, thermally robust electronics packaging and system design.

Gess noted that instead of using costly integrated circuits, the industry often substitutes thermal test vehicles — dummy chips that simulate the thermal characteristics of a functioning microchip, but at a far lower cost. HP is developing its own 3D thermal test vehicle, according to Gess, a move that he applauds.

“The last thing you want to do is find out there’s a problem with your chip design after you’ve sent it to fabrication,” he said. “It’s just too late to change the design. You need thermal test vehicles so that you can determine what cooling problems you might run into.”

Pushing the limits of technology

In a third study, funded by the NSF, Gess is working to solve a critical problem in electronics: ensuring that the microelectronics used in powerful, high-frequency communication and radar systems don’t overheat. Microelectronics used in advanced wireless communication and radar are known to generate a lot of heat. One of the key challenges is that the cooling system must control heat but without covering any part of the antenna array, which would trap the radio signals. Gess and his team are experimenting with sending coolant as close as possible to the microelectronics through the backplane.

“As we push the boundaries of technology — building systems that are faster, more compact, and more powerful — managing heat becomes one of the biggest barriers to performance and reliability,” Gess said. “This research could lead to more powerful, reliable, and sustainable communication systems that are crucial for future technologies on Earth and in space.”