Manufacturing in the United States is thriving. Last year, manufacturing sector output was more than double what it was 20 years ago, according to the U.S. Bureau of Labor Statistics.

“Manufacturing is changing,” said Karl Haapala, associate professor of advanced manufacturing. “The deployment of new information, sensing, and control technologies as well as advances in materials science and processing are driving these changes. Industry wants engineering graduates who understand those intersecting domains.”

The 2000s saw a decline in overall manufacturing employment. Most of the jobs lost were held by low-skilled workers. Since 2010, there has been a resurgence of manufacturing jobs, but there remains a dire and growing need for highly skilled production workers and engineers. It is predicted that 2 million new manufacturing jobs will be created in the U.S. over the next 10 years.

In fall 2018, to meet industry’s changing needs, the College of Engineering launched a new undergraduate program that combines majors in manufacturing engineering and mechanical engineering.

“Manufacturing is highly interdisciplinary,” Haapala said. “It requires understanding product design and development, as well as understanding how an entire manufacturing enterprise operates.”

For many years, Oregon State has offered a dual major in manufacturing engineering and industrial engineering, which allows students to focus on the industrial, or organizational, side of manufacturing — learning to develop processes and systems that are efficient and effective.

Now, with the new mechanical and manufacturing engineering dual major, students have the option to focus more on the product development side — translating initial concepts into physical items that can be competitively produced.

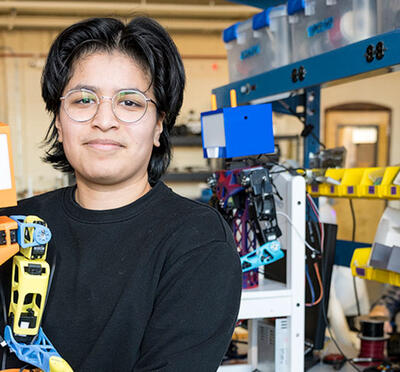

Dustin Harper, a junior and one of the first students to pursue the new degree, says he is excited to take on the challenge.

“Manufacturing is highly interdisciplinary. It requires understanding product design and development, as well as understanding how an entire manufacturing enterprise operates.”

“There’s often a disconnect between the engineers working on the manufacturing floor and those designing the product,” Harper said. “I want to be able to bridge that gap. A lot of the real-world issues we’ll be facing require knowledge from different fields. They might require some materials science knowledge or some chemistry; they might require some understanding of force, statics, or dynamics analysis.”

This is exactly what the new dual major program is intended to provide its students.

“I get to wear both hats a little bit,” Harper said. “And I get to explore the flexibility of design while gaining better insight into how things are actually made.” Kathy Hu, a sophomore, was also drawn to the flexibility offered by the degree. She says that while she enjoys mechanical engineering, she has a strong interest in understanding and devising processes, which is something the dual major allows her to lean into.

Hu also sees the new dual major as a competitive advantage once she graduates.

“The dual major in manufacturing engineering and mechanical engineering can take you anywhere,” she said. “Having the relevant class experience and projects related to manufacturing engineering, in particular, will definitely set me apart from a pure mechanical engineer and vice versa.”