Mechanical Engineering

Where beavers learn to build

One of engineering's most versatile disciplines

Mechanical engineering involves the design, analysis, and manufacture of mechanical systems, as well as the creation of new materials. By advancing technology in many industries, including automotive, aerospace, energy, healthcare, automation, and more, mechanical engineers are solving some of society’s most challenging problems.

Oregon State's record of success attracts world-class faculty who have achieved global prominence in signature research areas, such as advanced manufacturing, materials science, industrial and systems design, sustainable energy, robotics, and thermal-fluid science. Our highly collaborative environment also benefits students who are inspired to solve real-world challenges.

Degree Types

Locations

Corvallis

Cascades

Online

Our Faculty

Explore our faculty's expertise and research.

Contact our industry relations team to discuss partnerships and other opportunities.

Cutting-edge research

We create a safer, smarter, more resilient world through major contributions to fields that range from advanced manufacturing, materials science, sustainable energy, aerospace, and robotics.

Advanced Manufacturing

Developing advanced technologies to manufacture new and existing products

Design Engineering

Using design processes to facilitate the creation of new products and technologies

Thermal-Fluid Science

Engineering the transport of matter and energy from the molecular to megawatt scale

Next Generation Materials and Devices

The use of structural materials, electronic ceramics, energy materials, sensors

Mechanical Engineering Excellence & Discovery

Mechanical engineering touches nearly every facet of our lives

Oregon State researchers have contributed breakthroughs in numerous fields, such as advanced manufacturing, robotics, next-gen materials, and aerospace.

- New methods to improve production of advanced alloys

- Advanced techniques in additive manufacturing

- Breakthroughs in advanced materials for aerospace propulsion and nuclear fusion

- Innovations in robotics controls for real-world applications

- Advanced understanding of energy efficiency and sustainable energy systems

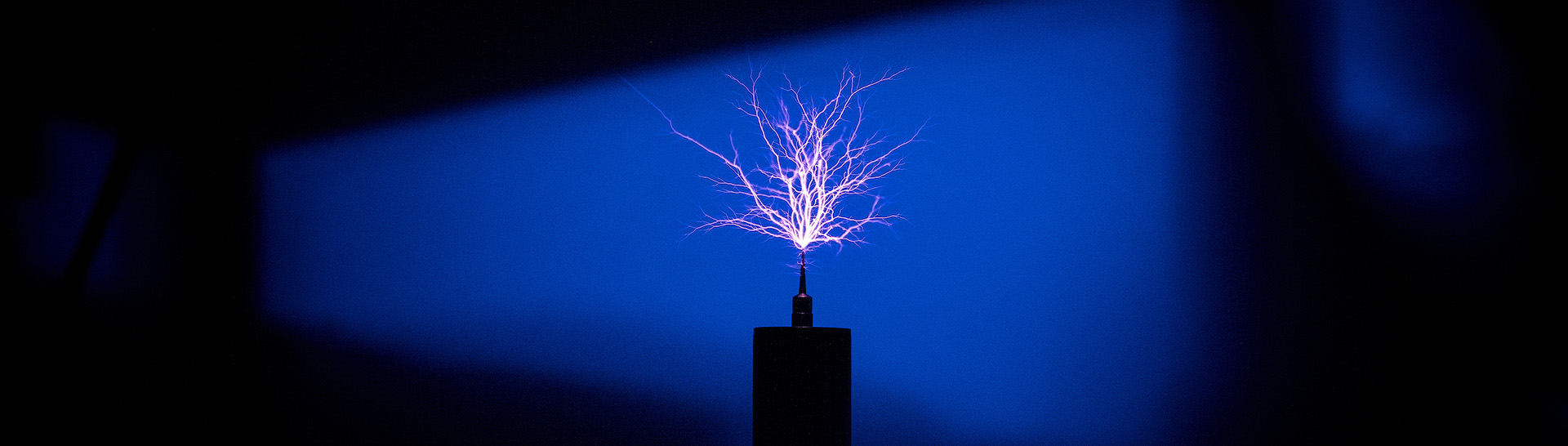

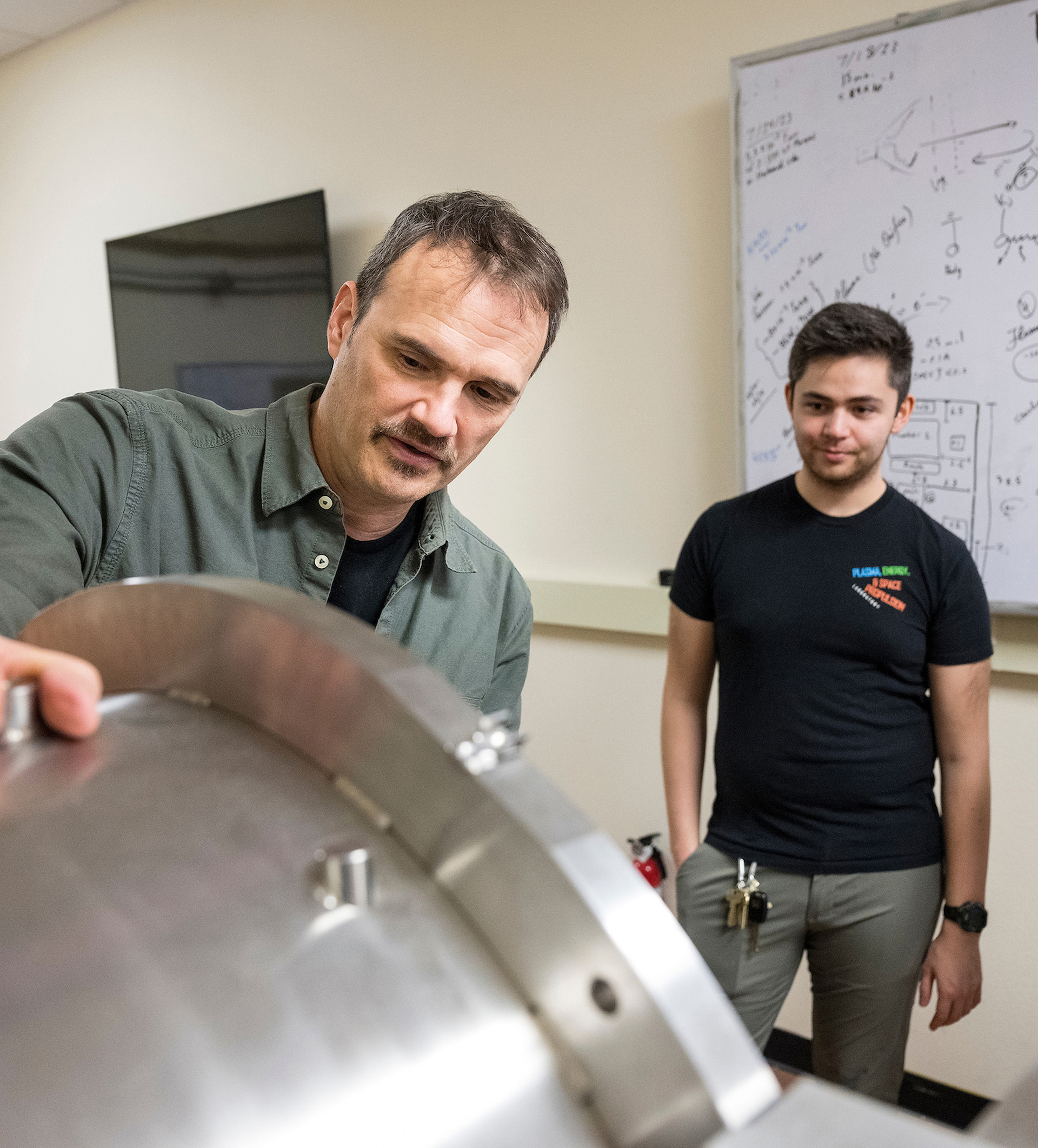

Surviving the extremes

Richard Wirz explores next-gen materials that will withstand the harsh environments of plasma thrusters and fusion reactors.

Degree Types

Locations

Corvallis

Cascades

Online

Our Faculty

Explore our faculty's expertise and research.

Get in Touch

Partnerships

Contact our industry relations team to discuss partnerships and other opportunities.