iLabs

SHOP HOURS

Monday through Friday: 8:30am – 5:00pm

Users requiring access outside of normal hours should reach out to iLabs.Shop@oregonstate.edu to determine After Hours eligibility, generally requiring written approval from a faculty advisor.

Mission

The College of Engineering Innovation Labs is a service center and shared resource intended to provide hands-on technical education, manufacturing/fabrication capabilities, research assistance, professional development, and design support to students of the College of Engineering and the greater OSU community.

We provide safe workspace and meaningful support to individuals, organizations, and CoE faculty and staff. Additionally, we offer prototyping and manufacturing services for groups across the OSU community to assist with product development and research projects.

iLabs staff is comprised of full-time faculty and classified staff, as well as part-time student employees drawn from across OSU, possessing a wide breadth of manufacturing expertise running the gamut of contemporary processes and techniques.

We are driven by a passion for Making in all of its forms, and strive to maintain a collaborative space where students, professors, and faculty from all backgrounds can thrive and innovate.

Register for Qualification Training

iLabs is available to any student who is a member of the College of Engineering (COE). To gain access to iLabs spaces, students must complete a series of qualifications to ensure proper training.

Completion of Orientation and Shop Basics is required for ALL subsequent qualifications.

To register for the new, entirely online Shop Basics please contact iLabs.Shop@oregonstate.edu to be added to the Canvas page.

Training Schedule

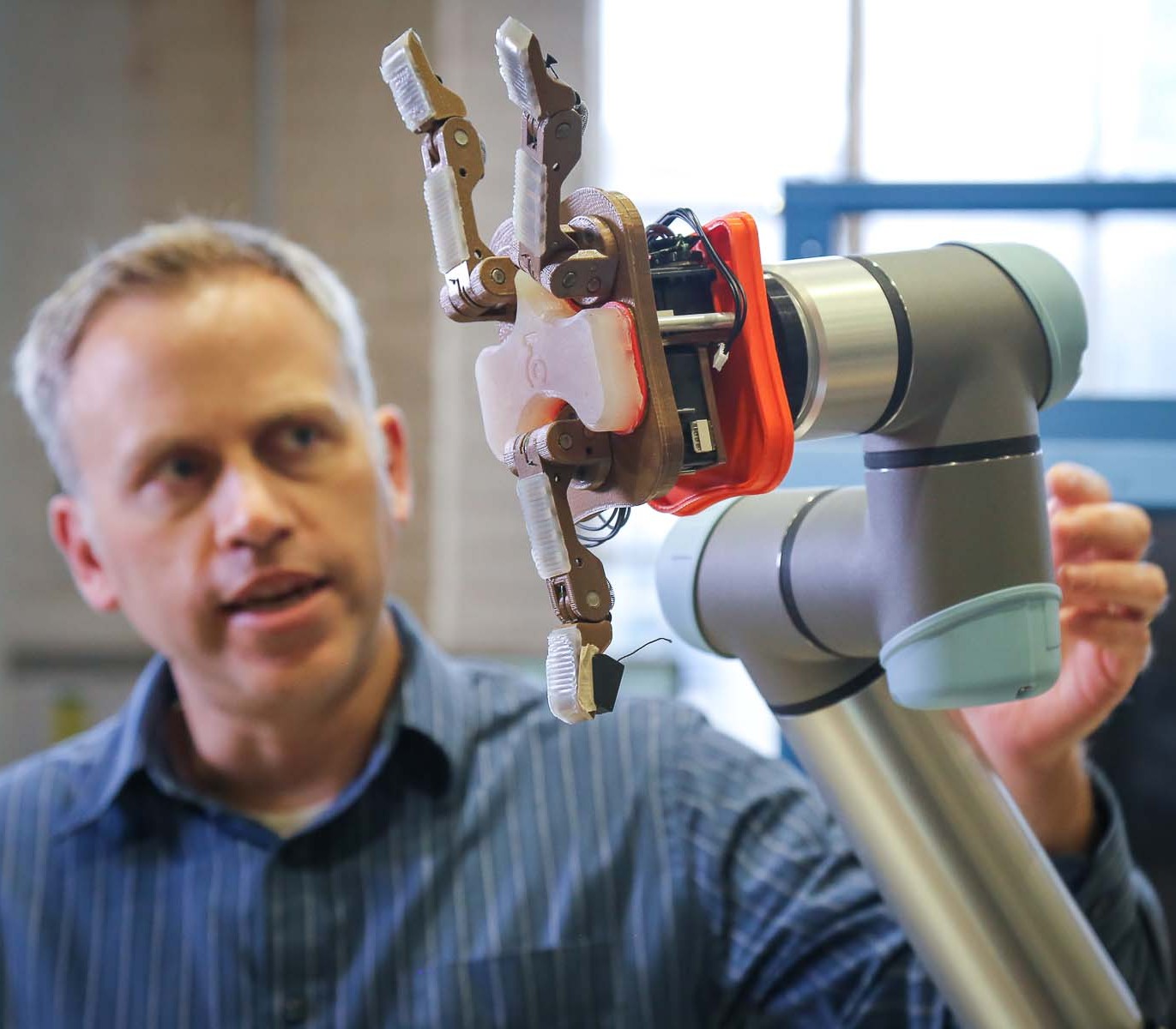

There are a variety of research projects in progress year-round in COE. The iLabs provides a place for students to explore the many aspects of research, including design, machining, and final assembly. With our skilled staff, outstanding training courses, and excellent equipment, we are able to produce parts that meet or exceed the high level of precision demanded by research.

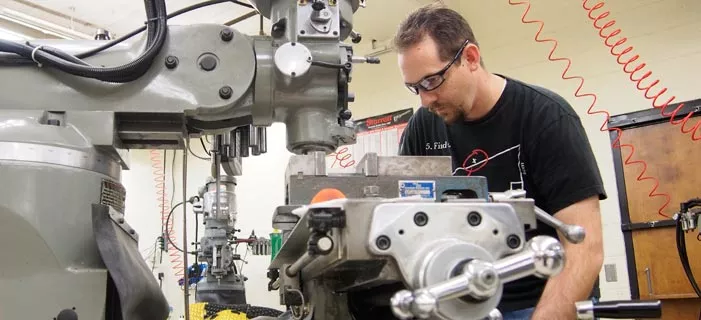

From pre-engineering to graduate level, COE students utilize iLabs facilities and expertise for completing course assignments, capstone design projects, research activities, and more. Such efforts may involve a variety of manufacturing techniques including welding, machining, CNC machining, rapid prototyping, and sheet metal work.

Reserve Space

The Innovation Labs (iLabs) offer a range of work and storage spaces designed to support various projects and activities.

Eligibility for Reservation

- COE Capstone Projects: Students or teams working on capstone projects within the College of Engineering (COE) are eligible to reserve space.

- COE Clubs: Officially recognized clubs within the COE can reserve space for their meetings, projects, or events.

- COE Instructional Activities: Faculty and staff conducting instructional activities or workshops under the COE can reserve space for these purposes.

Reserve Use of iLabs Spaces

While most ad-hoc use does not require pre-arrangement, approval must be gathered ahead of time for any activity requiring significant dedicated workspace or prolonged use.

If you are interested in hosting a class or activity within iLabs, or if you have a project that requires substantial/long-term space allocation within one of our spaces, please reach out to iLabs.Shop@oregonstate.edu with a general description of your intended use for review.

General guidelines and requirements can be found in the linked document below.

iLabs Space Use – Classes, Events, and Labs

Storage Facilities

We offer a range of on-site storage totes for users or groups interested in storing their projects within iLabs. Totes can be locked closed and/or secured to their storage shelves via user-provided locks or cables, and all storage is offered on a first-come, first-served basis.

- Standard Storage: The majority of the storage available in iLabs consists of plastic totes. The dimensions of these totes are 24 inches in length, 18 inches in width, and 15.4 inches in height.

- Limited Large-Size Storage: For projects that cannot be accommodated within the standard plastic totes, a limited number of larger storage spaces are available. These are allocated on a first-come, first-served basis or based on specific project requirements.

Please reach out to iLabs.Shop@oregonstate.edu to coordinate storage reservations, including any identifying information for you or your group, along with the number of the storage tote(s) you intend to use.

All reservations expire at the end of each Spring term, and items remaining in the space after the end of the term will be subject to disposal at staff discretion.

Request Prototyping

Need something made?

The iLabs uses a variety of CAD/CAM software tools, including Fusion 360, Autodesk, and EdgeCam, for solid modeling and computer-aided manufacturing.

Projects completed in iLabs range from undergraduate course assignments to faculty research tools. Items may be fabricated from a variety of materials including plastics, composites, ceramics, and metals.

If you are interested in having iLabs manufacture parts, assemblies, or other items, please contact iLabs.Shop@oregonstate.edu to start a quote.

Reserve Equipment

To ensure machine availability, all shop usage requires booking an appointment prior to coming in to work on your project.

For a full list of reservable iLabs equipment, please visit our RELMS page.

Equipment Qualifications

iLabs is home to a wide variety of both foundational and advanced manufacturing equipment, supported by our expert staff. Our primary mission is to ensure students have access to trainings and equipment intended to ensure academic success and development of fundamental concepts and intuition around manufacturing processes likely to be encountered over the course of their careers.

Access to facilities and equipment is managed through our internal qualification system, generally consisting of an informational overview leading up to an in-person training, followed by completion of a practical project designed to demonstrate sufficient comprehension of the training content. Certain trainings may require one or more prerequisite trainings, the full Qualification Tree for which can be accessed by clicking the button below.

For a more detailed listing of available qualifications, or to see the list of qualifications currently under development, please refer to the relevant button below.

Manufacturing Processes

Find details of various manufacturing processes – for the lathe, mills, and saws – that we offer through iLabs.