The pandemic didn’t stop Bahman Abbasi’s desalination research. In this third episode, we learn about the successful lab-scale demonstration of his team’s technology and the next steps toward its commercialization. Plus, the team takes on a new project to clean up wastewater from oil and gas production.

[MUSIC: “The Odd numbers,” by Curtis Cole, licensed through Artlist.io]

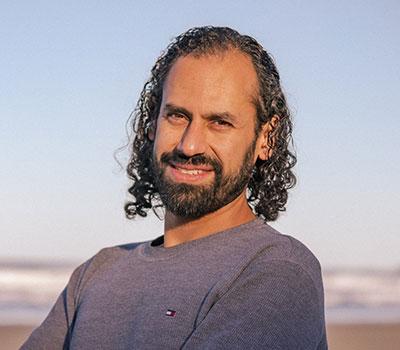

RACHEL ROBERTSON: Hi friends! Welcome back to the Quest for Clean Water, the story of a research project to invent a new technology for water desalination. I’m your host, Rachel Robertson, and over the last four years I’ve been chatting with Bahman Abbasi who is leading the project. We skipped doing an interview in 2020 for obvious reasons, but we caught up on my back porch in the summer of 2021 (hence, the chirping birds you might hear in the background). And, although much of the world seemed to come to a halt during that intervening time … Bahman had a lot to tell me.

[MUSIC: “The Ether Bunny,” by Eyes Closed Audio, licensed under CC by 3.0]

ROBERTSON: From the College of Engineering at Oregon State University, this is Engineering Out Loud.

ABBASI: Just a few weeks ago, for the first time, we demonstrated the whole module in its entirety, and desalinated highly saline water and made potable water out of it. It's a big milestone for us. And to explain why that matters so much, is, there are two main aspects to the design. One is this novel cycle that we are trying to patent: Would it actually work? And the second one is: Would it work economically? And we now have proven the first one.

[MUSIC: “The Venus,” by Yotam Agam, licensed through Artlist.io]

ROBERTSON: The salinity of seawater is about three-and-a-half percent. Their demonstration produced potable water from a saline solution that was 15% salt by mass. Why is that important? You may remember from the first episode that we talked about how other desalination systems produce a concentrated brine that becomes an environmental hazard. So, one of the main advantages of Bahman’s thermal-based system was eliminating the brine. The second was to reduce fouling (basically, the parts get clogged up with salt), which is a common problem for current desalination systems.

ABBASI: We set out to solve these two problems. And we did them by replacing the membranes and the pack beds with a cyclonic separator. It's a cyclone, it rotates the flow, and it separates out all the salts. And we do this by fully humidifying air with water. So, we entirely evaporate the brine, the saline mixture, such that we get only humid air and only suspended salt particles. And then we convey that through a cyclone or through the centrifugal forces, the salts and only salts are separated out and humid air moves back, cools down, condenses out the water, and we have clean water and salts, and no brine, and nothing that fouls in the system.

ROBERTSON: So, this description sounds very much like the description that you gave me in 2018. Did anything change in that process?

[MUSIC: “Vacuum,” by Buddha Kid, licensed through Artlist.io]

ABBASI: You are correct to pick up on that because a lot of the times you have a vision and as you execute that, major things about it change. For this one, we were fortunate enough that no, it is exactly what we envisioned. Sometimes along the way, we envisioned changing the cycle and doing different things with it and we attempted multiple side avenues. And every time we came back to our original idea, that what we thought about in the first place is actually working the best. Now, there are things that did change. We had to make some adjustments, add a little component here, a little component there, to make sure that the thermodynamics is consistent. The fluid mechanic features that we want, are obtained. But the cycle is unaltered. It is only the execution that required some tweaking.

ROBERTSON: I should point out that the system they successfully demonstrated is at lab scale, so there is still a way to go before it can be commercially viable. But they met the proposal’s energy, cost, and durability targets.

ABBASI: We have demonstrated 10 liters, just over three gallons per hour, which is what our current contract with the U.S. Department of Energy requires us to do. We did it a year ahead of schedule. And the next step is to increase it ten-fold, we want to go to a hundred liters per hour. And then the final stage is … we're hoping for several tons per day of clean water. And we are pursuing that path. It's still a few years out, but we are in much stronger place than we were two and a half years ago when we spoke. And all we had were drawings on the whiteboard.

[MUSIC: “Silent Transmission,” by Tamuz Dekel, licensed through Artlist.io]

ROBERTSON: It’s actually quite stunning how far the research has come. One of the things that helped was additional funding from the U.S. Department of Energy through a program called the American-Made Challenges: Solar Desalination. One hundred and sixty-two teams across the nation competed for prizes, and 19 advanced in the competition to the second round, receiving $50,000. In 2021, Bahman’s team had passed through another round to be one of eight semifinalists, earning them another $350,000 to support designing the system.

ABBASI: Yeah. That is one of the most exciting parts of this. To just give you the background on that, in research circles, it is a known problem that you can develop something and demonstrate a piece of technology and method in the lab. And then there is funding to take a big pilot scale and commercialize it. But there is something in between — between the lab scale demonstration and a pilot scale that there's so little funding and support available for it, that in these circles, it is referred to as the valley of death. That you can get it there, but it dies before it ever sees the light of day. So, the U.S. Department of Energy has this initiative to identify promising lab-scale technologies and provide funding for them to bridge this gap.

ROBERTSON: In the next phase, their task was to fully design a pilot plant that can produce several tons of water per day. As part of that, Bahman formed a spin-off company that could lead the technology through the commercialization process. This is one of the ways that technologies invented at a university can get out into the world — other examples of spin-off companies from Oregon State included Agility Robotics and NuScale Power. Bahman’s company is called Espiku. Remember how I told you to hold that mountain metaphor from episode two in your mind? This is where it returns.

[MUSIC: “Evanescent,” by Tamuz Dekel, licensed through Artlist.io]

Espiku means white mountain in Luri, Bahman’s native language, and is also the name of a large mountain in Iran. Creating a company that would serve people’s needs has been a goal for Bahman – his white mountain to ascend. And he just got a step closer. Part of this step was identifying a team that could bring the technology to market.

ABBASI: We have a design company identified, C-Zero, which is a very capable design outfit out of Fort Collins, Colorado, very experienced in this field. And we're very excited to have identified Orenco here in Oregon in Southern Oregon. And they specialize in containerized wastewater treatment systems, which is perfect match for what we do because our technologies, both for desalination and wastewater treatment are distributed containerized units.

ROBERTSON: OK, I have a small confession to make. I haven’t been telling you the full story. You may have noticed that Bahman just mentioned wastewater treatment. Back in 2019, Bahman got another award from the Department of Energy. This one is to clean up wastewater produced by oil and gas operations, such as fracking, and other industries like mining. At first, I wanted to focus on just one project, but I realized there is an important story to tell about of the ripple effects of invention. So, here we go. Bahman explains why industrial wastewater was a tricky problem to solve.

ABBASI: The difficulty with cleaning these myriad wastewater sources is that there are so many different contaminants and pollutants in them. So many different organics, and inorganics that if you want to focus on individual ones, first, you need to know what all you're dealing with, which you often don't, and certain removal processes focus narrowly on a particular class of contaminants. So, you have to do multiple, multiple processes to get a series of contaminants out. So, we turned the problem on its head. We said, “We know for a fact that we want the water out, and that's just one contaminant.”

ROBERTSON: That’s a little bit confusing since he refers to water as a contaminant, but that’s what he means by turning the problem on its head. He focused on getting the water out of the contaminants.

[MUSIC: “When the Sunrise,” by Yehezkel Raz, licensed through Artlist.io]

ABBASI: So, let's design the process such that it gets only water out. And, inevitably, it will also take out other contaminants, pollutants that behave exactly like water or very, very, similar to water. If you have something that thermodynamically behaves like water, we do capture some of that too, but that's just such a small sliver of your overall contaminants that you can really clean it up by focusing on water.

ROBERTSON: At this point, the team had a lab scale demonstration that took very dirty water, of 75% purity and got it to 98% purity. They applied for a patent on this process just as they had for the water desalination system. I asked him how similar these two systems were for desalination and wastewater treatment.

ABBASI: They have similarities in some aspects of the thermodynamic cycle. So, in both, we use air to humidify to absorb the water, and then we condense out the water, but all the rest of it is actually quite different. How the cycle operates is that we use some sort of surface evaporation to only evaporate water and those contaminants that are more volatile than water, that evaporates before water. So, what we get is a humid stream that has water and light volatile contaminants. And then we very carefully modulate the temperature of that. So, we can condense out only water and leave the volatiles in gaseous phase. So, water condenses out in liquid, but the volatiles stay in gaseous phase and they are ejected from the system. What we are left is only clean water.

So, just to recap, it's a two-stage process. We evaporate. So, we leave behind all the heavy contaminants that don't evaporate easily. And then from the fraction that evaporates, we modulate it, such that we only extract water and leave the volatiles in gaseous phase.

ROBERTSON: Cool.

[SOUND OF A GARBAGE TRUCK GOING BY]

ABBASI: [LAUGHS]

ROBERTSON: How much …

WILL HAVENAER: Just a couple seconds.

ROBERTSON: Yeah, yeah. Right. It’s garbage day.

ABBASI: It’s rather late isn’t it.

ROBERTSON: The garbage truck interruption was a reminder that we were still functioning in a pandemic world, which was hard to believe given all that Bahman and his team had accomplished. Research labs were closed for several weeks at the beginning of the pandemic until Oregon State could establish safe lab protocols. It was a situation with a silver lining.

ABBASI: Sometimes in the research world, you focus so much on performing your experiment, fixing your experiment that you lose the bigger, broader picture.

[MUSIC: “When the Sunrise,” by Yehezkel Raz, licensed through Artlist.io]

So, it helps to step back, look at the whole picture again and rethink it. So, we a did lot of that, and good things came out of it. We had time to really complete some of our reporting and writing requirements. We revamped a lot of our numerical simulation analysis, we did some really good analytical work and it's set us up to be in a better place, have a better handle of the overall work when we reentered the lab and continued to do our experiments. We had a fresher, better mindset about it.

ROBERTSON: One of the major threads through this story is the diversity of students and staff who were instrumental in the success of the project — a project that requires students and postdocs who were experts in different areas, but who also came from many different backgrounds.

ABBASI: Having that diversity of background and bringing everyone together has created such a rich environment — respectful, and really the values of equality and diversity that we all aspire to. I reap the rewards of it every day. And as it happens, just this morning, one of our students was practicing for his master's thesis defense, and this team spirit, how close everyone was and how earnestly everyone was trying to help and elevate each other was striking.

[MUSIC: “Sprawling,” by Borrtex, licensed through Artlist.io]

I told my team, it just warms my heart to see this team come together and mesh so nicely of all different colors and backgrounds and religions and languages of origin.

ROBERTSON: The master’s presentation by Ifeanyi Uwaoma, who is from Nigeria, also weaves in another thread of this season, the personal investment the team has in the work.

ABBASI: He showed a picture of young African children getting little rusty pots and skimming off a muddy pool of water to drink. And this student who's about to get his master's degree said, “That was me when I was a child.” And it really, really resonated with me. That was his drive. He came here to do this, and I'm really hoping that we are just a few years away from being able to deploy these systems in those communities for those people.

ROBERTSON: Thanks for joining me on this journey. We have one more episode to go. This episode was produced by me, Rachel Robertson. Steve Frandzel, Owen Perry and Chris Palmer gave me constructive criticism. Will Havnaer helped with the recording and Cooper Mitchell gave me a hand with polishing the audio.

ABBASI: It has felt quite magical at times, I have to say.

ROBERTSON: Yeah, yeah. Well, it’s also been a lot of work, are you getting any sleep yet?

ABBASI: We talked about this in our first interview. I look forward to getting that sleep when this is all over. So, not yet. Give me another year.

ROBERTSON: OK, OK.