As an undergraduate student in electrical and computer engineering at Oregon State University, Bradley Heenk and his fellow students often printed 3D parts to use in their class projects. Since many students needed custom-printed parts at the same time, Heenk saw this as opportunity to start a business and help his classmates get quality parts more quickly.

Having spent two years taking community college courses, Heenk was already a junior when he transferred to Oregon State. It was soon after that he started Corvallis3D in a closet in his house with a few 3D printers.

While he was happy to provide this service to students, Heenk also wanted to grow his start-up while continuing to go to school, he developed a website and reached out to prospective customers. Corvallis3D became a partner with a global company that opened up opportunities for them to create products for customers across the globe.

“This was a big shift for the business,” said Heenk, who then was able to lease an office and buy more printers. He also was able to hire an employee to keep up with the orders.

Heenk ran his business on the side as he continued to work toward his degree. He an internship lined up at Tektronix for the summer after his junior year but because of the pandemic, that was delayed for a year.

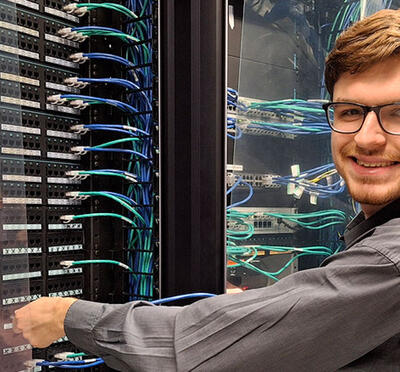

After graduating with a bachelor’s degree in electrical and computer engineering and a minor in computer science in 2021. Heenk did the internship at Tektronix and eventually accepted a full-time job there as a software quality engineer. Working fully remotely from Corvallis, he is able to also continue running Corvallis3D.

“I work on the business in the evenings and on the weekends, and since I have an employee who helps fill the orders, I can do both,” Heenk said. “There are also many processes that I’ve been automating.”

To help automate the order fulfilling process so there are fewer hands-on steps they need to take to get the parts printed, Heenk built an API, or an application programming interface. He also automated much of the shipping process.

People often ask Heenk about the types of orders he gets. “It could be a cup holder. It could be an enclosure for something. It could literally could be anything,” he said.

Like many entrepreneurs, Heenk plans to eventually expand the company, perhaps moving it to the Portland area and acquiring bigger clients.

“This is a good start,” he said. “I like to do some planning but I like to take things day-by-day. I don’t want to make any big crazy moves all at once.”