Emma Sparkman doesn’t expect to do much welding after she graduates with a bachelor’s degree in mechanical engineering, but in the event the need arises, she’ll be ready.

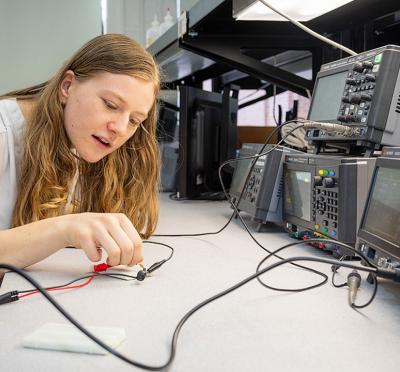

Sparkman, along with five other College of Engineering students, learned welding, machining, electronics, and other applied manufacturing processes (including computer-aided design and programmable logic controllers) in a summer 2023 practicum conducted by the Oregon Manufacturing Innovation Center.

Students from across Oregon who have second-year status during the summer are eligible to participate. In addition to gaining hands-on experience in several keystone trade skills, each practicum participant, under the guidance of OMIC’s expert technical staff, develops and completes an advanced manufacturing project involving subtractive manufacturing, additive manufacturing, or robotics and electronics. Upon finishing, each participant receives a pre-trade certificate for advanced manufacturing, as well as an appropriate OSHA certification.

OMIC, located in Scappoose, Oregon, is a collaboration of industry, higher education, and government. Aimed at strengthening the state’s manufacturing sector and attracting investment throughout the state and region, OMIC’s activities include training and the development of new tools, manufacturing techniques, and technologies. The organization is funded primarily by the state of Oregon and through membership fees.

“The experience opened my eyes to how manufacturing works,” said Sparkman, who opted for the practicum’s subtractive manufacturing track. “It helped me realize that when I’m a mechanical engineer, I’ll have to consider the capabilities and limitations of different manufacturing processes in my designs. I’ll also be able to communicate more clearly with the people who work in manufacturing, and that will help me to become a better engineer.”

Students in the practicum receive a salary, just as they would at an internship, but there’s a fundamental difference between the two approaches to experiential learning, according to John Parmigiani, research associate professor in mechanical engineering and director of industry relations for the School of Mechanical, Industrial, and Manufacturing Engineering.

“Internships are similar to regular jobs where students exchange their time and service in exchange for pay and, hopefully, valuable experience,” Parmigiani said. “But practicums, particularly this practicum, are different. They emphasize learning; they don’t expect students to function as employees. Every part of it focuses on learning and developing new skills, and it’s all a good fit for students who are interested in engineering careers that take them into the field or that are associated with manufacturing operations.”

Luke Frugia, a computer science major, was in the same practicum cohort as Sparkman. He built a deadlift jack for weightlifting in the welding class and an herb grinder for his parents in the machining class. For his advanced manufacturing project, he opted for the robotics track, and ended up designing and building a self-playing chess set. The opposing sides play using open-source AI chess software for which Frugia wrote code to facilitate moves. Electromagnets attached to a gantry system under the transparent chessboard pull the game pieces to coordinates as directed by the AI or by instructions typed into a keyboard. Frugia created all of the pieces using 3D printing.

“They really want you to learn at the practicum, and everyone on the staff was very supportive,” Frugia said. “If there was something that interested me and that I wanted to pursue further, like robotics-related technology, someone would take the time to show me. The program was focused on teaching and not on getting something from me in return.”

Both Sparkman and Frugia are returning to OMIC for internships this summer. Frugia is continuing his emphasis on robotics, but Sparkman decided to switch her focus from subtractive to additive manufacturing because of its importance in producing tools for medical research — a field she might pursue in her career.

“If you’re passionate about something, OMIC will 100% find a way to help you learn more about it,” Sparkman said. “The practicum experience also boosted my self-confidence. If something was particularly challenging and it took me some extra effort to figure it out, the staff was always there to assist me and encourage me to stick with it. Learning engineering can be intimidating sometimes, but the practicum reinforced my decision to study mechanical engineering.”

For more information, contact John Parmigiani, john.parmigiani@oregonstate.edu