The High Temperature Test Facility (HTTF) is a one-quarter scale integral test facility model of the Modular High Temperature Gas Reactor. The facility is capable of operating at temperatures like those expected in a loss of forced convection cooling accident. The nominal working fluid is helium although other gases can be used. The facility is configured to simulate a variety of postulated depressurized conduction cooldown (DCC), pressurized conduction cooldown (PCC) and normal operations events.

Purpose

The purpose of the test facility is twofold: to validate the correlations that are currently used to model relevant heat transfer and fluid flow phenomena required for the integrated simulation of the prismatic core phenomena; and generate results that can be used to validate different simulation methodologies applied in the gas cooled reactors modeling.

Facility Design

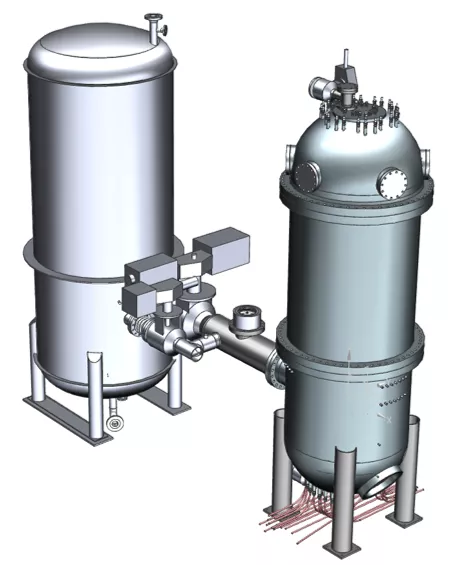

The facility is built in modular design to allow core reconfiguration from prismatic to pebble design.

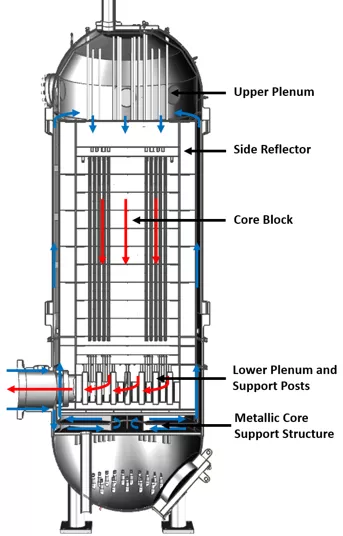

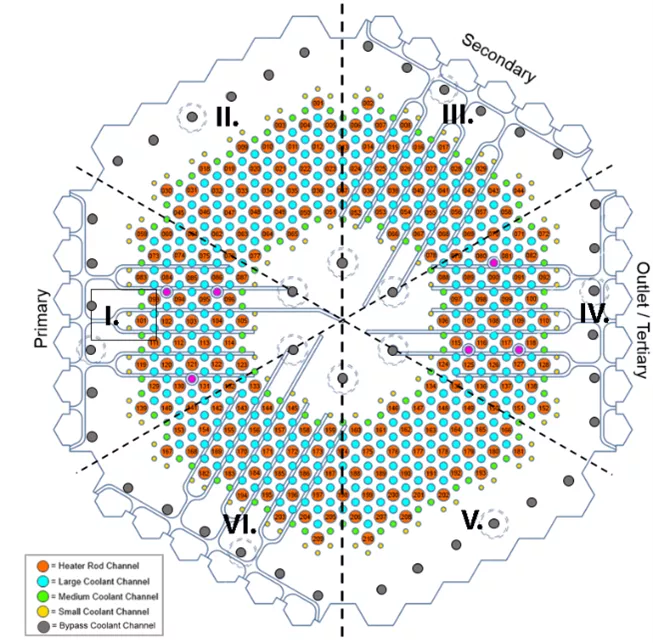

In the current configuration, the graphite prismatic block structure in the MHTGR is simulated by ceramic blocks to capture prototypical core temperature profiles. The HTTF reactor core is built of 10 hexagonal core blocks that are made of a cast ceramic, Greencast 94-F. The reactor core is surrounded by reflectors on each side (2 upper reflectors, 3 bottom reflectors, and side reflectors). The side reflectors are made of a cast ceramic, ShotTech SiC 80 while the top and bottom reflectors are also made of Greencast 94-F. In addition, there are 3 separate structures designed to model the core exit chamber: lower plenum roof, lower plenum (the chamber that houses 163 support posts), and lower plenum floor.

The heating system is a network of electrically heated graphite rodlets/dog bones. The facility is equipped with the network of electrically heated graphite rods that produce approximately 2.2 MWth. There are 210 heater rods arranged in 10 heater banks, with 3 heater legs per heater bank. Each heater leg consists of 7 heater rods.

Detailed facility technical specification and instrumentation plan are available here:

- Facility Description Report: https://www.osti.gov/biblio/1599410-osu-high-temperature-test-facility-design-technical-report-revision

- Instrumentation Plan: https://www.osti.gov/biblio/1599628-instrumentation-plan-osu-high-temperature-test-facility-revision

Section view through the HTTF RPV and helium flow path.

HTTF system CAD model.

Arrangement of coolant channels, bypass channels, and heater rods channels in the HTTF core block.

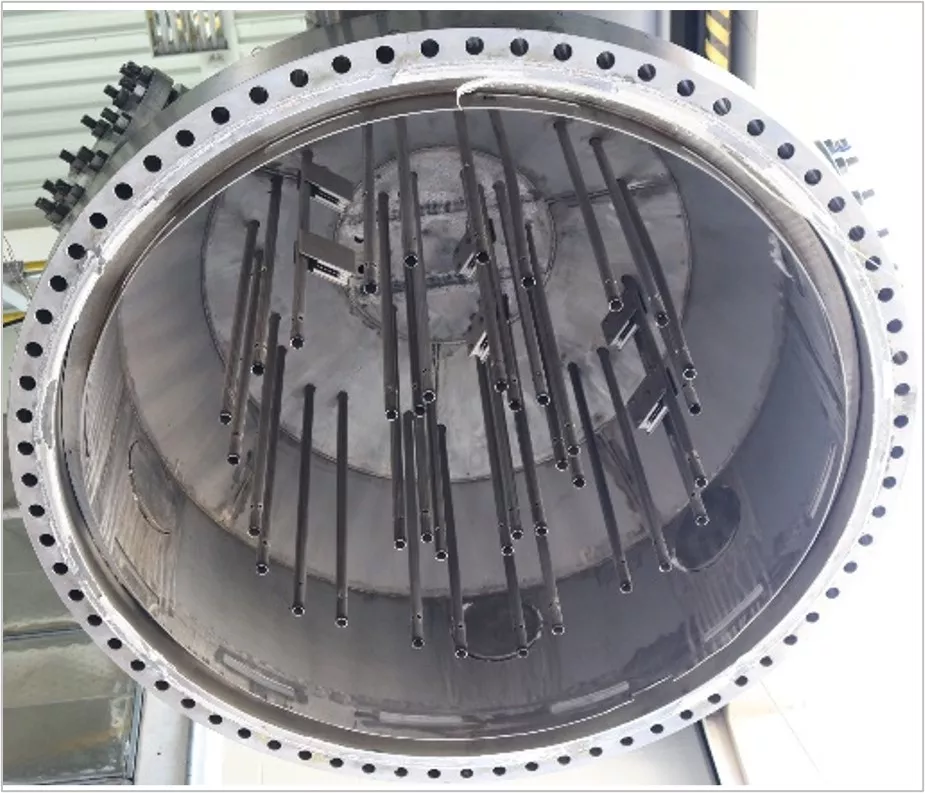

HTTF upper head with instrumented guide tubes.

OSU HTTF at a glance

- Integral Effects Test (IET) facility

- Provides data for thermalhydraulic codes validation

- Primarily designed to model the DCC transient

- Variety of break size and location (upper, lower and cross-duct)

- Four distinct phases of the transient (depressurization, lock-exchange flow,

molecular diffusion and natural circulation) - Reactor Cavity Cooling System as boundary condition

- Other scenarios can be examined: PCC and Normal operation

- Working fluids: Helium and Nitrogen

- Reference design: MHTGR

- Facility Scaling

- 1/4 length scale

- 1/4 diameter scale

- 1/8 pressure scale (0.8 MPa)

- Temperatures: T max =1400˚C, T in =259˚C, T out =687˚C

- Electrically Heated: max. Power ~2.2 MW

- Operates under NQA-1 program

Tests Performed

Selected HTTF Test Acceptance Reports are available at https://www.osti.gov/

| Test # | Procedure # | Test title | Phenomena |

| 1 | PG-01 | Pre-Operation |

Characterization |

| 2 | PG-02 | Circulator and System Form Loss Characterization | Characterization |

| 3 | PG-06 | Facility Gas Conditioning | Characterization |

| 4 | PG-07A | Primary Loop and RCST Volume Determination | Characterization |

| 5 | PG-08 | Break Valve Characterization | Characterization |

| 6 | PG-09 |

Steam Generator Secondary Side Volume Determination |

Characterization |

| 7 | PG-21 |

Lock Exchange Flow and Diffusion Test with 500°C average Gas Temp |

DCC |

| 8 | PG-22 |

Lock Exchange Flow and Diffusion Test with 125°C average Gas Temp |

DCC |

| 9 | PG-23 |

Lock Exchange Flow and Diffusion Test with 375°C average Gas Temp |

DCC |

| 10 | PG-24 |

Lock Exchange Flow and Diffusion Test with 250°C average Gas Temp |

DCC |

| 11 | PG-26 |

Low Power (<350kW) Double Ended Inlet-Outlet Crossover Duct Break, 2 Heaters |

DCC |

| 12 | PG-27 |

Low Power (<350kW) Complete Loss of Flow, 2 Heaters |

PCC |

| 13 | PG-28 | Low Power (<350kW) Lower Plenum Mixing | Mixing |

| 14 | PG-29 |

Low Power (<350kW) Double Ended Inlet-Outlet Crossover Duct Break, Hybrid Heater |

DCC |

| 15 | PG-30 |

Low Power (<350kW) Lower Plenum Mixing, Constant Temperature |

Mixing |

| 16 | PG-31 |

Low Power (<350kW) Pressure Vessel Bottom Break with Restored Forced Convection Cooling |

DCC |

| 17 | PG-32 | Low Power (<350kW) Asymmetric Core Heatup | Heatup |

| 18 | PG-33 | Zero Power Long Term Cooldown | Cooldown |

| 19 | PG-34 |

Low Power (<350kW) Asymmetric Core Heatup Full Hybrid Heater |

Heatup |

| 20 | PG-35 |

Low Power (<350kW) Zero Power Crossover Duct Exchange Flow and Diffusion |

DCC |

Selected HTTF related papers

M.S. Theses and Ph.D. Dissertations

- Magnusson, J. E. (2011). Pressure Effects on Density-Difference Driven Stratified Flow:

CFD Model of a DCC event in the HTGR.

https://ir.library.oregonstate.edu/concern/graduate_thesis_or_dissertat… - King, B. M. (2012). Natural circulation scaling of a pressurized conduction cooldown

event in the upper plenum of the modular high temperature gas reactor. Oregon State

University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP71138131480… - Utberg, J. E. (2013). Nitrogen concentration sensitivity study of the lock exchange

phenomenon in the high temperature test facility. Oregon State University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP99830858018… - Aldridge, R. J. (2013). Scaling study of the depressurized conduction cooldown event in

the high temperature test facility using RELAP5-3D/ATHENA. Oregon State University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP71188086950… - Cadell, S. R. (2013). Development of a binary mixture gas composition instrument for

use in a confined high temperature environment. Oregon State University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP71946894300… - Castañeda, J. A. (2014). Scaling analysis of the OSU high temperature test facility

during a pressurized conduction cooldown event using RELAP5-3D. Oregon State University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP71205404870… - Gutowska, I. (2015). Study on Depressurized Loss of Coolant Accident and its Mitigation

Method Framework at Very High Temperature Gas Cooled Reactor. Oregon State University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP71229129960… - Gradecka, M. (2015). Modification of Lower Plenum Structure for Mixing Promotion

during Normal Operation of the High Temperature Gas Cooled Reactor. Oregon State

University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP71228899830… - Glass, M.(2017). Effect of Initial Conditions and Depressurization on Lock Exchange

Flow After a Depressurized Conduction Cool-Down Event in the High Temperature Test

Facility. Oregon State University.

https://search.library.oregonstate.edu/permalink/f/ueodtl/CP71255064270… - Brawley, L. (2018). Feasibility of GOTHIC for a Pressurized Conduction Cooldown Event

in the High Temperature Test Facility. Oregon State University.

https://ir.library.oregonstate.edu/concern/graduate_thesis_or_dissertat… - Brumback, K. (2020). Effect of Initial System Temperature on Initiation of Natural

Circulation during a Depressurized Conduction Cooldown Event in the High

Temperature Test Facility. Oregon State University. https://ir.library.oregonstate.edu/concern/graduate_thesis_or_dissertat…

Journal Papers

- Gutowska, I., Woods, B. G., & Cadell, S. R. (2019). CFD modeling of the OSU High

Temperature Test Facility inlet plenum flow distribution during normal operation. Nuclear

Engineering and Design, 353, 110216. https://doi.org/10.1016/j.nucengdes.2019.110216 - Gradecka, M. J., & Woods, B. G. (2016). Development of thermal mixing enhancement

method for lower plenum of the High Temperature Test Facility. Nuclear Engineering

and Design, 305, 81–103. https://doi.org/10.1016/j.nucengdes.2016.02.043 - Andre, M. A., Burns, R. A., Danehy, P. M., Cadell S. R., Woods B. G., and Bardet, P.

M., “Velocimetry during depressurized conduction cooldown events in the

HTTF," Nuclear Engineering and Design, 341, pp. 406-414, 2019. - Andre, M. A., Burns, R. A., Danehy, P. M., Cadell S. R., Woods B. G., and Bardet, P.

M., “Development of N2O-MTV for low-speed flow and in-situ deployment to an

integral effect test facility," Exp Fluids (2018) 59:14.

Conference Papers

- Gutowska I., Halsted J., Schlamp N., Woods B. G, Manera A., Petrov V., Balestra P

Building Conduction Cooldown Scenarios Experimental Validation Database for HTGRs,

NURETH-19, Brussel, Belgium, March 2022 - Gutowska I., Woods B. G, CFD Assessment of LOFA Intra Core Natural Circulation in

the High Temperature Test Facility, NURETH-18, Portland, Oregon, August 2019. - Gutowska I., Cadell S. R., Woods B. G., CFD Air Ingress Analyses on High Temperature

Test Facility, ANS Winter Meeting, Washington DC, US, October/November 2017). - Brumback, K. E., Woods, B. G., & Cadell, S. R. (2017). Overview of Shakedown Testing

for the High Temperature Test Facility. Transactions of the American Nuclear Society,

117, 1619. - Brumback, K. E., Cadell, S. R., and Woods, B. G., “Temperature and Flow

Characteristics of the High Temperature Test Facility during Depressurized Conduction

Cooldown Testing,” Proceedings, Advances in Thermal Hydraulics 2018, Orlando,

FL, November 2018. - Andre, M. A., Bardet, Cadell S.R., and Woods B.G., “Velocimetry/Thermometry

Data Fusion from DCC Tests in the HTTF,” Proceedings, International 18th International

Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH 18), Portland,

Oregon, August, 2019. - Andre, M. A., Bardet, P. M., Danehy, P. M., Burns, R. A., Cadell S.R., and Woods

B.G., “Non-Intrusive Velocity Measurements with MTV During DCC Event In the

HTTF,” Proceedings, International 17th International Topical Meeting on

Nuclear Reactor Thermal Hydraulics (NURETH 17), Xi’an, China, September, 2017.